Diaphragm Pump

Maintenance Tips: Extending the Life of Your Diaphragm Pump

Maintenance Tips: Extending the Life of Your Diaphragm Pump

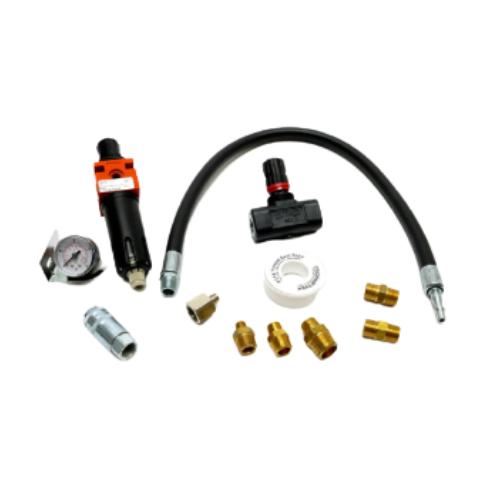

Proper maintenance is crucial for maximising the operational lifespan and efficiency of your diaphragm pump. This presentation explores comprehensive maintenance practices, troubleshooting tips, and preventative measures to help you avoid costly downtime and repairs whilst ensuring optimal performance.

Understanding Diaphragm Pump Technology

Diaphragm pumps are positive displacement pumps that use a flexible diaphragm to create variable volume chambers. During operation, the diaphragm:

- Creates suction and discharge strokes to move fluid

- Provides a hermetic seal between the drive mechanism and pumped fluid

- Enables safe handling of abrasive, corrosive, and viscous fluids

Understanding this fundamental design is essential for effective maintenance, as the diaphragm is the critical component most vulnerable to wear.

Common Diaphragm Pump Types

Essential Routine Maintenance Procedures

Trouleshooting Common Issues

Industry-Specific Maintenance Considerations

Maximising Pump Lifespan: Best Practices

Preventative Maintenance Schedule

- Develop a comprehensive maintenance calendar based on operating hours

- Train operators on basic daily inspection procedures

- Keep detailed maintenance logs for trend analysis

- Stock critical spare parts to minimise downtime

Environmental Considerations

- Protect pumps from extreme temperatures

- Shield from excessive dust or humidity

- Ensure proper ventilation for air-operated models

Operational Guidelines

- Avoid running pumps dry whenever possible

- Maintain proper pressure settings as specified by manufacturer

- Implement “soft-start” procedures for viscous fluids

- Clean thoroughly after handling particulate materials

Staff Training

Invest in comprehensive training for maintenance personnel on:

- Proper disassembly and reassembly techniques

- Correct torque specifications for fasteners

- Early warning signs of potential failures