Diaphragm Pump

5 Common Mistakes When Installing an Air-Operated Diaphragm Pump (AODD) – And How to Avoid Them

5 Common Mistakes When Installing an Air-Operated Diaphragm Pump (AODD) – And How to Avoid Them

Proper installation is critical for the performance and longevity of your AODD pumps. This guide will help you avoid costly errors and maximise efficiency

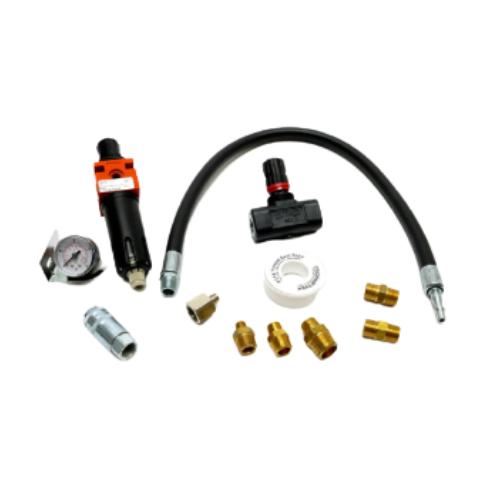

Mistake 1: Using Incorrect Air Line Size and Pressure

Too small an air line starves the pump of compressed air, reducing flow and causing erratic operation.

Excessive air pressure stresses diaphragms, shortening pump life significantly.

Solution:

Match air line size to manufacturer specifications and regulate pressure carefully with proper gauges and regulators.

Mistake 2: Ignoring Chemical Compatibility of Pump Materials

The Problem

Pump components (elastomers, castings, hardware) must resist the chemicals being pumped.

Using incompatible materials causes swelling, corrosion, and premature failure.

The Solution

Consult chemical compatibility guides from manufacturers and select appropriate materials accordingly.

Consider factors such as pH level, temperature, and concentration of chemicals being pumped.

Mistake 3: Reducing Suction Line Size or Length Improperly

Mistake 4: Overlooking Operating Temperature Limits

Warning: Temperature Extremes Damage Pumps

Pump materials degrade or lose flexibility outside recommended temperature ranges (e.g., above 104°C or below freezing).

High temperatures cause cracking and premature failure, while low temperatures reduce diaphragm flexibility and lifespan.

Solution:

Choose pumps materials specifically rated for your fluid temperature range and continuously monitor operating conditions.

Mistake 5: Neglecting Proper Priming and Air Exhaust Setup

The Issue

Failing to bleed air pockets or improperly routing exhaust air leads to icing, cavitation, and erratic cycling.

Muffler icing is common in humid environments and significantly reduces efficiency.

The Fix

Follow manufacturer priming steps carefully, install air line dryers and heaters when needed, and route exhaust piping to safe locations.

Case Study: How a Small Air Line Caused Major Downtime

The Situation

A chemical plant used a 1/4″ air hose instead of the recommended 3/8″ line for their AODD pump installation.

The Result

The pump was starved of air, causing flow to drop by 30% and diaphragms to fail prematurely, resulting in costly downtime.

The Solution

The maintenance team upgraded the air line to the proper diameter and installed a regulator; pump life was extended by 40%

Correct vs Incorrect Suction Line Installation

Correct Installation

- Short, straight suction line

- Full port diameter maintained

- Minimal bends and restrictions

- Proper sealing at all connections

Incorrect Installation

- Long, narrow suction line

- Reduced diameter at connections

- Multiple bends causing restrictions

- Potential air leaks at fittings

Best Practices Summary for AODD Installation

Maximise Your AODD Pump Life and Efficiency

Proper installation prevents costly downtime and repairs that can impact your operations.

Always consult pump manuals and manufacturer experts before installation.

Remember: Small changes in setup yield big gains in reliability and performance.

Your pump’s longevity depends on the care you take during installation.