Diaphragm Pump

AODD Pump Failure: 10 Common Problems and How to Avoid Them

AODD Pump Failure: 10 Common Problems and How to Avoid Them

Air-Operated Double Diaphragm (AODD) pumps are trusted across industries for their reliability, safety, and ability to handle difficult fluids. But as with any mechanical system, improper installation, incorrect sizing, and poor maintenance can lead to performance issues or complete failure.

Understanding the root causes of AODD pump failure is the key to preventing downtime and extending pump life. Below, we break down the 10 most common reasons AODD pumps fail — and exactly how to avoid them.

10 Common Causes of AODD Pump Failure

What Causes AODD Pump Failure?

This section explains each failure mode with causes, symptoms, and prevention steps — plus links to relevant spare parts and accessories.

1. Insufficient or Restricted Air Supply

A restricted or undersized air supply is one of the most common causes of AODD pump failure.

According to the EPA compressed air efficiency guidelines:

Poor-quality air systems dramatically reduce pump output and efficiency.

Symptoms

-

Slow or inconsistent cycling

-

Reduced flow

-

Pump won’t start

How to Prevent It

-

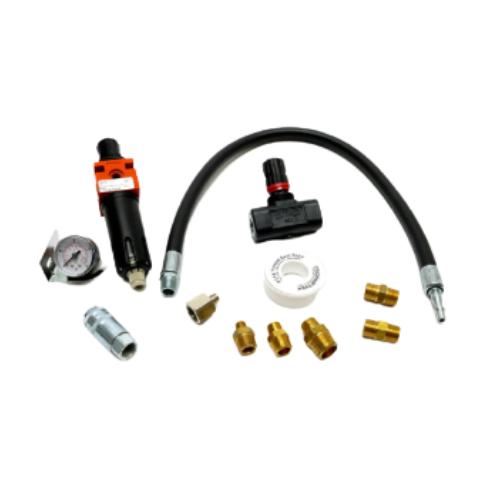

Use correct air-line size

-

Install air filtration and regulation equipment

-

Maintain clean, dry air supply

2. Worn or Damaged Diaphragms

The diaphragm is the primary wear component. Chemical attack, excessive pressure, or age most commonly lead to failure.

Symptoms

-

Loss of flow

-

Air escaping from exhaust

-

External fluid leaks

How to Prevent It

-

Replace diaphragms routinely

-

Choose compatible diaphragm materials

-

Maintain proper air pressure

3. Debris or Contamination in the Pump

Debris blocks check valves, damages diaphragms, and stops pumps from priming.

How to Prevent It

-

Install inline strainers

-

Flush new systems before use

-

Use clean fluid supply

4. Incorrect Pump Sizing

Undersized pumps operate at maximum stress, while oversized pumps use excessive air and wear components prematurely.

How to Prevent It

-

Calculate proper flow and pressure

-

Consider viscosity, lift height, and friction losses

-

Use manufacturer performance curves

5. Chemical Incompatibility

Material failure is common when pumps are exposed to incompatible chemicals.

Refer to official FDA material compatibility guidance

How to Prevent It

-

Always check compatibility charts

-

Use PTFE for strong solvents

-

Use Santoprene for general-purpose fluids

-

Use EPDM for water-based fluids

6. Worn or Sticking Check Valves

Check valves control fluid direction. When they fail, the pump loses suction or flow.

How to Prevent It

-

Replace check valves during diaphragm changes

-

Inspect for swelling, abrasion, or cracking

7. Excessive Suction Lift

Exceeding the pump’s suction capability introduces air, causing cavitation and diaphragm shock.

How to Prevent It

-

Keep suction lines short and direct

-

Use flooded suction

-

Ensure airtight connections

8. Running at Incorrect Air Pressure

Too much pressure damages diaphragms; too little pressure stalls the pump.

The OSHA compressed air regulations provide safety guidelines

How to Prevent It

-

Use a regulated, stable air supply

-

Follow manufacturer pressure limits

9. Using Non-ATEX Pumps in Hazard Zones

Incorrect pump selection in explosive atmospheres can lead to severe safety risks.

Refer to the official EU ATEX equipment guidelines

How to Prevent It

-

Always use ATEX-rated pumps

-

Check zone classification

-

Ensure proper grounding

10. Lack of Routine Maintenance

Poor maintenance is the single biggest cause of AODD pump failure.

How to Prevent It

-

Replace diaphragms every 6–12 months

-

Inspect check valves regularly

-

Keep spare kits on hand

-

Monitor cycle counts

Conclusion: Preventing AODD Pump Failure Starts with Good Practice

Most cases of AODD pump failure can be prevented by following good installation practices, ensuring material compatibility, maintaining clean air supply, and checking diaphragms regularly.

If you want expert help with pump selection, troubleshooting, or sourcing spare parts:

Contact DiaphragmPumps.co.uk

FAQs

Restricted air supply and worn diaphragms.

6–12 months depending on the duty cycle and fluid type.

Yes — but extended dry running reduces diaphragm life.

Watch for air leaks, loss of flow, or fluid escaping the chamber.