Diaphragm Pump

5 Questions to Ask Before Buying a Diaphragm Pump

If you’re considering buying a diaphragm pump, you probably already know they’re versatile, durable, and capable of handling a wide range of fluids. But with so many types, sizes, and materials available, how do you choose the right one for your application?

To make the decision easier, here are five essential questions to ask before buying a diaphragm pump. These will help you avoid costly mistakes and ensure your pump delivers reliable performance for years to come.

1 - What fluids will you be pumping?

Not all diaphragm pumps are created equal — the type of fluid you’re moving makes a big difference in the material you choose.

-

Aggressive chemicals like acids or caustics require diaphragms and wetted parts made from PTFE (Teflon) to resist corrosion.

-

Solvents and hydrocarbons often run best with Viton diaphragms, which stand up to swelling and degradation.

-

Food and beverage products must use FDA-approved or hygienic materials such as Santoprene or PTFE, ensuring compliance with sanitary standards. Check the FDA Food Contact Standards

-

Slurries or abrasive fluids need tougher materials such as reinforced Santoprene that can withstand wear from solids.

👉 Choosing the wrong material can mean rapid diaphragm failure — but matching materials to fluids increases service life and safety.

2 - What Flow rate and pressure do you need?

Sizing Considerations When Buying a Diaphragm Pump

Sizing your pump correctly is crucial. Too small, and your process starves. Too large, and you waste energy and wear out parts prematurely. Flow rate is one of the biggest factors to consider when buying a diaphragm pump.

Start by calculating:

-

Required flow rate (litres per minute or gallons per minute).

-

Maximum discharge pressure (bar or PSI).

For example, if your application requires 80 L/min at 6 bar, you shouldn’t buy a pump rated for exactly 80 L/min. Instead, choose one that comfortably delivers 100 L/min at 7–8 bar. This buffer ensures consistent performance without over-stressing the pump.

👉 Remember: undersizing causes poor flow and cavitation, while oversizing burns through compressed air and diaphragms.

3 - Where will the pump be installed?

Your installation environment has a direct impact on the type of pump you should choose.

-

Factory floor: Standard aluminium or stainless steel pumps often suffice, depending on fluids.

-

Outdoor sites: Look for weatherproof housings and corrosion-resistant materials.

-

Hazardous (ATEX) zones: Pumps must carry ATEX certification for use in explosive atmospheres. View ATEX directives (EU)

-

Washdown areas: Hygienic pumps with polished stainless steel and sealed air valves are essential for food or pharmaceutical settings.

👉 The wrong choice here could mean compliance issues, safety hazards, or premature failure.

4 - What maintenance & downtime can you tolerate?

Even the best diaphragm pumps require maintenance — the key is understanding how often and how disruptive it will be.

-

Diaphragm lifespan typically ranges from 6–12 months depending on duty cycle, fluid, and material.

-

Preventive maintenance such as checking air valves, seals, and diaphragms reduces the risk of sudden failure.

-

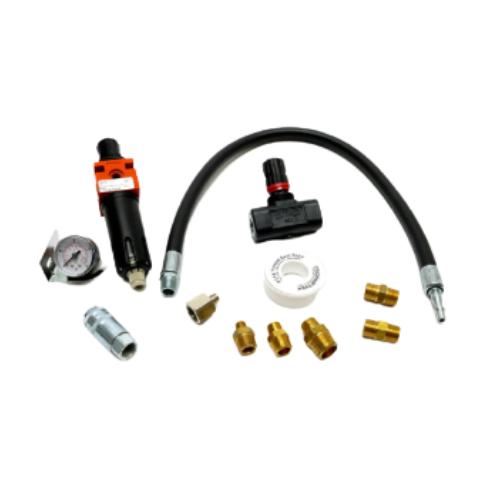

Spare parts availability matters. Keeping a maintenance kit (diaphragms, seals, check valves) in stock can cut downtime from days to minutes.

-

With proper care, a diaphragm pump body can last 10+ years — it’s the wear parts that need attention.

👉 If your process can’t tolerate unplanned downtime, invest in quality pumps and maintenance routines.

5- What's your budget (and lifetime cost)?

It’s tempting to buy the cheapest pump on the market — but the lowest upfront price doesn’t always mean the lowest cost over time.

-

Cheap pumps often suffer frequent failures, higher air consumption, and more spare part replacements.

-

Quality pumps may cost more initially, but they reduce unplanned downtime, use less energy, and have longer service intervals.

Think in terms of total cost of ownership (TCO):

A £300 saving today could cost you £1,000/year in extra downtime and repairs.

👉 Over a few years, the “expensive” pump often works out far cheaper.

Conclusion: Buying a Diaphragm Pump with Confidence

When buying a diaphragm pump these 5 questions need to be asked. Asking the right questions before buying a diaphragm pump can save you money, time, and frustration. By considering the fluids, flow rate, environment, maintenance, and lifetime cost, you’ll be far better equipped to select a pump that performs reliably in your application.

If you’re unsure which pump is right for you, our experts can help. 👉 Contact us today or browse our full range of diaphragm pumps.

What is the lifespan of a diaphragm pump?

With proper maintenance, diaphragms last 6-12 months, while the pump body itself can last 10 years or more.

Can diaphragm pumps handle solids?

Yes, many AODD pumps can handle slurries and solids without damage.

Do diaphragm pumps need priming?

Most AODD pumps are self-priming, making them easy to start up and install.